Turbochargers are an essential component for the performance of high-performing vehicles. Their importance lies in their ability to increase the engine power by compressing the air that enters the engine. With more compressed air, the engine can burn more fuel to generate more power. To achieve this, the turbocharger uses a turbine that is powered by the exhaust gases from the engine. With increased usage over time, these critical components can wear out and need replacement.

But, what happens when a turbocharger is damaged? The answer to this question necessitates the exploration of the turbocharger’s bearing and seal system. This article will examine the mechanics of the turbocharger bearing and seal system and provide an understanding of the causes of failure and how to prevent them.

Mechanics of the Turbocharger Bearing and Seal System

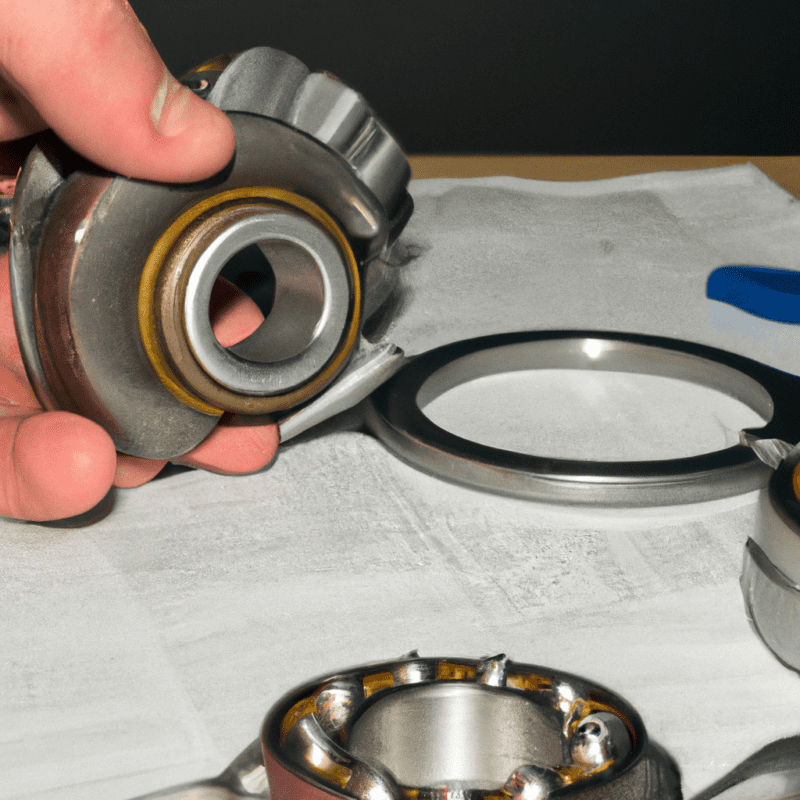

The turbocharger bearing and seal system consists of primary and secondary components. The primary components include the turbine and compressor blades, the exhaust and the compressor housings, and the shaft that connects the turbine and compressor wheels. Another component is the journal bearing system that supports the rotating shaft.

The journal bearing system is composed of the turbine and compressor-side bearings that support the rotation of the shaft. These bearings are made of a material that has a low coefficient of friction, so the shaft can rotate smoothly around the center. The bearing’s location ensures that the compressor and turbine wheels’ rotation remains stable and does not encounter any vibrations.

Moreover, the bearing system is also lubricated with engine oil that reaches the bearing through a feed line. This oil helps prevent the bearings from degrading over time due to wear.

The secondary components in the turbocharger bearing and seal system include the oil seal and the thrust bearing. The oil seal is located on the turbine side of the turbocharger and prevents engine oil from reaching the intake air. The thrust bearing, located between the turbine and compressor wheels, resists the axial force that is produced when the compressor wheel is spinning at high speeds.

Turbocharger Bearing and Seal System Failure

Turbocharger bearing and seal system failure is one of the most common issues that can lead to turbocharger failure. One of the most common reasons for system failure is due to long periods without oil changes. The lack of oil change leads to the degradation of the journal bearings, leading to irreversible damage to the journal bearing system. The damage can also cause excessive heat to be generated within the turbocharger, which further damages the turbocharger’s internal components.

Another cause of bearing system failure is due to oil contamination. Dirt, unfiltered air, and engine combustion products can get into the oil and clog the tiny oil passageways within the bearing system. The contaminants will cause damage to the bearing system and increase the chances of system failure.

Preventing Turbocharger Bearing and Seal System Failure

Several best practices can prevent turbocharger bearing and seal system failure. One of these practices is regular oil changes. Oil changes should be made per the vehicle manufacturer’s recommended schedule. Remember the turbocharger’s bearing system is continuously dependent on sufficient lubrication to function correctly.

Another preventive measure is proper air filtration. Air filtration keeps dirt and contaminants from getting into the oil and causing damage. A clogged air filter could cause the turbocharger’s bearings and seals to become dirty too, which can cause system failure.

Lastly, it is essential to perform regular inspections of the turbocharger. Visual inspections of the component’s seals, hoses, and bolts can help detect any system issues early. If there are any signs of leakage or wear, the component should be fixed or replaced to prevent costlier damages.

Frequently Asked Questions (FAQs)

1. What is the lifeline of a turbocharger bearing and seal system?

The lifespan of a turbocharger bearing and seal system is dependent on the maintenance practices. If there are good maintenance practices such as regular oil changes, proper air filtration, and regular component inspections, the bearing and seal system can last for several years.

2. How do I know if my turbocharger bearing and seal system is damaged?

One of the clear signs of damaged turbocharger component is excessive smoking, a sign that anything from the turbocharger bearing and seal system could be wrong. When you notice an increase in smoking, your turbocharger may only require minor repairs. However, if the problem is not dealt with, the turbocharger may fail completely.

3. Can I repair my damaged turbocharger or should I replace it?

The answer to this question is dependent on the level of damage to the turbocharger. If the damage is minor and caught early, repairs can be done to the turbocharger component. But, if the damage is extensive, it is advisable to replace the component. Replacing the component will ensure that you have a longer-lasting and functional turbocharger system.

Leave a Reply