Best Turbocharger Manufacturers and Suppliers in the World

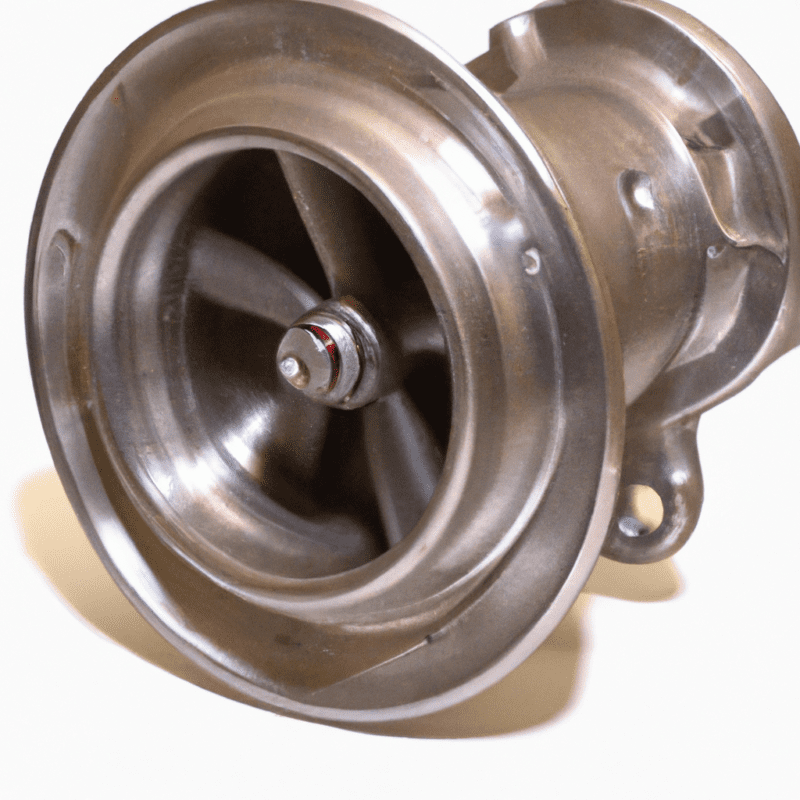

Turbochargers are an important component in most modern automobiles. They are designed to increase the efficiency of the engine by compressing the air intake and increasing the density of the air being supplied to the engine. This results in a higher power output and fuel economy. There are a number of turbocharger manufacturers and suppliers in the market today. In this article, we will explore the top turbocharger manufacturers and suppliers in the market.

Honeywell Turbo Technologies

Honeywell Turbo Technologies is a major player in the turbocharger market. The company designs, develops, and manufactures turbochargers for a wide range of applications. Their products are used in heavy-duty trucks, marine vessels, heavy equipment, racing cars, and passenger vehicles.

The company has a diverse portfolio of products that cater to a wide range of customers. Their products are known for their durability, reliability, and high performance. Honeywell Turbo Technologies has a strong global presence and operates in more than 100 countries. Their products are sold through a network of distributors and dealers.

Garrett Advancing Motion

Garrett Advancing Motion is another major player in the market. The company has a rich history in the development and manufacturing of turbochargers. Their products are used in passenger cars, commercial vehicles, industrial engines, and racing applications.

Garrett Advancing Motion has a strong focus on innovation and technology. The company invests heavily in research and development to bring new products to the market. Their products are known for their high performance, reliability, and fuel efficiency. The company has a strong global presence and operates in more than 30 countries. Their products are sold through a network of distributors and dealers.

BorgWarner

BorgWarner is a global leader in turbocharger technology. The company designs, develops, and manufactures turbochargers for a wide range of applications. Their products are used in passenger cars, commercial vehicles, marine vessels, and racing applications.

BorgWarner has a diverse product portfolio that caters to a wide range of customers. Their products are known for their high performance, durability, and fuel efficiency. The company has a strong focus on innovation and technology. They invest heavily in research and development to bring new products to the market. BorgWarner has a strong global presence and operates in more than 60 locations across the world. Their products are sold through a network of distributors and dealers.

IHI Corporation

IHI Corporation is a Japanese company that is a major player in the turbocharger market. The company has a diverse product portfolio that caters to a wide range of customers. Their products are used in passenger cars, commercial vehicles, marine vessels, and industrial engines.

IHI Corporation has a strong focus on technology and innovation. The company invests heavily in research and development to bring new products to the market. Their products are known for their high performance, durability, and fuel efficiency. IHI Corporation has a strong global presence and operates in more than 30 countries. Their products are sold through a network of distributors and dealers.

Cummins Turbo Technologies

Cummins Turbo Technologies is a division of Cummins Inc. that focuses on turbocharger technology. The company designs, develops, and manufactures turbochargers for a wide range of applications. Their products are used in heavy-duty trucks, marine vessels, heavy equipment, and power generation applications.

Cummins Turbo Technologies has a diverse product portfolio that caters to a wide range of customers. Their products are known for their high performance, reliability, and fuel efficiency. The company has a strong focus on innovation and technology. They invest heavily in research and development to bring new products to the market. Cummins Turbo Technologies has a strong global presence and operates in more than 90 countries. Their products are sold through a network of distributors and dealers.

Frequently Asked Questions:

Q1. What is a turbocharger?

A: A turbocharger is a device that is used to increase the efficiency and power output of an engine. It compresses the air intake and increases the density of the air being supplied to the engine. This results in a higher power output and fuel economy.

Q2. What is the difference between a turbocharger and a supercharger?

A: A turbocharger and a supercharger are both devices that are used to increase the efficiency and power output of an engine. However, they work in different ways. A turbocharger is driven by exhaust gases, while a supercharger is driven by a belt that is connected to the engine. A turbocharger is more efficient at high speeds, while a supercharger is more efficient at low speeds.

Q3. What are the benefits of using a turbocharger?

A: The benefits of using a turbocharger include increased power output, improved fuel economy, and reduced emissions. Turbochargers are also simple and reliable in operation and require minimal maintenance. They are widely used in modern automobiles and heavy equipment.